Pumps

- Product List

- The Technology

GNH Series

Displacement:

24.5 ml/rev (G35)

Differential Pressure (max):

6.9 bar | 100 psi

System Pressure (max):

103 bar | 1500 psi

GMH Series

Displacement:

12.2 ml/rev (G25)

Differential Pressure (max):

8.7 bar | 125 psi

System Pressure (max):

103 bar | 1500 psi

GA Series

Displacement:

0.017 ml/rev (X21)

0.042 ml/rev (V21)

0.092 ml/rev (T23)

Differential Pressure (max):

5.2 bar | 75 psi

System Pressure (max):

21 bar | 300 psi

GAH Series

Displacement:

0.017 ml/rev (X21)

0.042 ml/rev (V21)

0.092 ml/rev (T23)

Differential Pressure (max):

5.2 bar | 75 psi

System Pressure (max):

345 bar | 5000 psi

GB Series

Displacement:

0.26 ml/rev (P23)

0.58 ml/rev (P25)

1.17 ml/rev (P35)

Differential Pressure (max):

8.6 bar | 125 psi

System Pressure (max):

21 bar | 300 psi

GC Series

Displacement:

0.811 ml/rev (M23)

1.82 ml/rev (M25)

3.48 ml/rev (M35)

Differential Pressure (max):

8.6 bar | 125 psi

System Pressure (max):

103 bar | 1500 psi

GD Series

Displacement:

3.48 ml/rev (M35)

Differential Pressure (max):

6.9 bar | 100 psi

System Pressure (max):

103 bar | 1500 psi

GJ Series

Displacement:

0.316 ml/rev (N21)

0.64 ml/rev (N23)

0.91 ml/rev (N25)

1.23 ml/rev (N27)

Differential Pressure (max):

5.5 bar | 80 psi

System Pressure (max):

21 bar | 300 psi

CA Series

Recommended Max Speed:

6,000 RPM

System Pressure (max):

14 bar | 200 psi

GAF Series

Displacement:

0.092 ml/rev (T23)

Differential Pressure (max):

17.2 bar | 250 psi

System Pressure (max):

21 bar | 300 psi

GJR Series

Displacement:

0.316 ml/rev (N21)

0.64 ml/rev (N23)

1.23 ml/rev (N27)

Differential Pressure (max):

5.5 bar | 80 psi

System Pressure (max):

21 bar | 300 psi

GLH Series

Displacement:

4.6 ml/rev (H21)

6.2 ml/rev (H23)

7.7 ml/rev (H25)

Differential Pressure (max):

8.6 bar | 125 psi

System Pressure (max):

103 bar | 1500 psi

External Gear - Cavity Style

Cavity style gear pumps consists of two or more rotating gears which interlock together. One of the gears is turned by a power source and drives the other gear(s). The spaces between the gear teeth carry the fluid from the inlet to the outlet. The gear interlace point prevents the fluid from returning to the inlet.

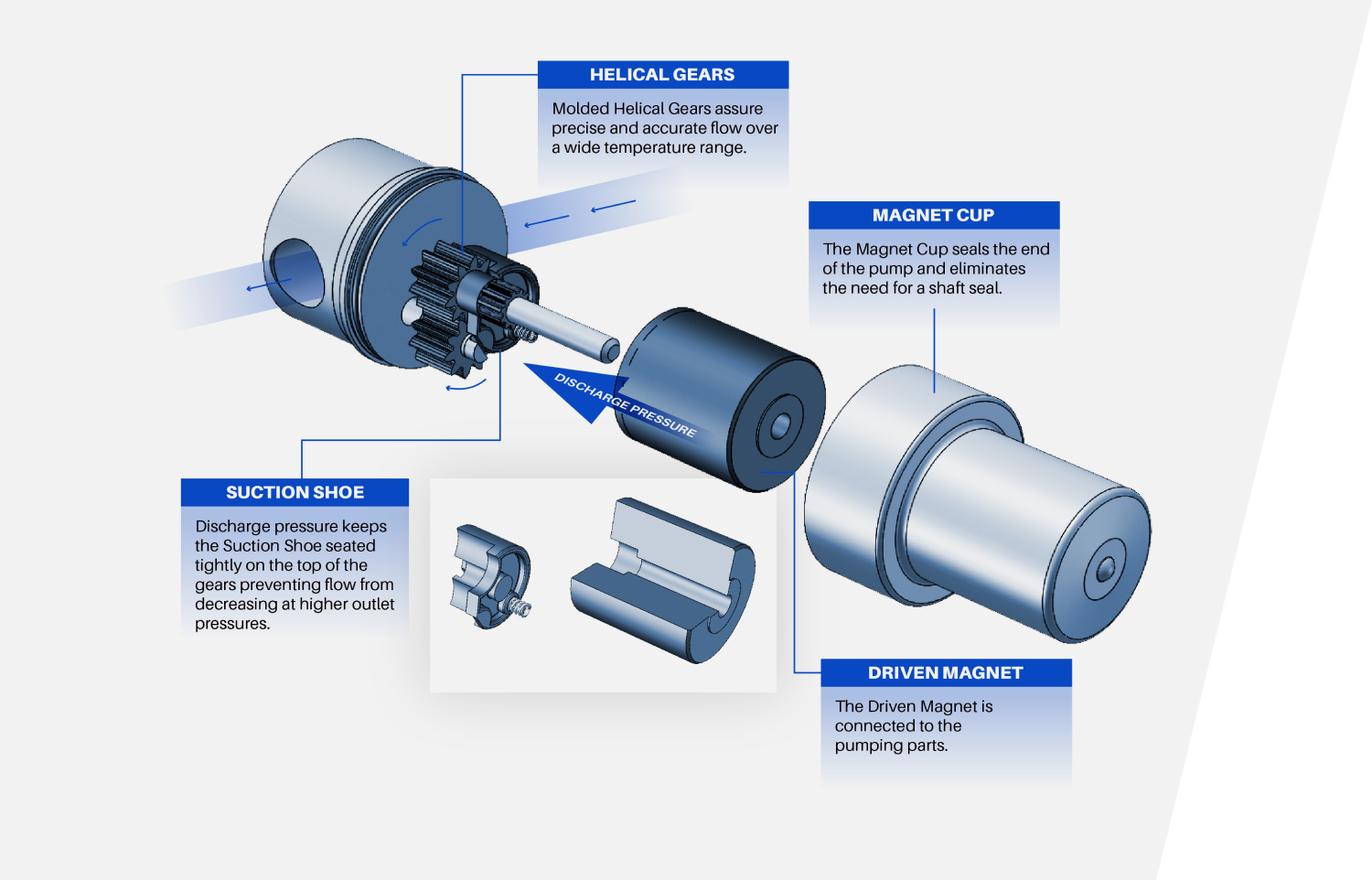

External Gear - Suction Shoe Style

Our trademark, patented suction shoe pressure-loaded gear pump design features a “suction shoe” that allows the pump to self-compensate for wear. Suction shoe pumps maintain high-volumetric efficiency, even at elevated pressures. Additional benefits include near-zero slip for accurate metering, long life, and more stable performance as pump components wear or thermally expand. The suction shoe pump, unlike any other gear pump on the market, self adjusts on the job for reliable, pulseless flow, and features easier maintenance with less downtime than standard pumps.

Centrifugal

Centrifugal pumps offer a reliable, simple, long-lasting design for higher flow applications. Using the unique magnetic drive technology, centrifugal pumps provide excellent chemical resistance and energy-efficient fluid delivery. Integrated impeller and magnet assemblies reduce the number of rotating parts to maximize pump life.

Centrifugal pumps consist of an impeller rotating within a casing. Liquid directed into the center of the rotating impeller is picked up by the impeller vanes and accelerated to a high velocity. When the liquid in the impeller is forced away from the center of the impeller, a reduced pressure is produced and consequently more liquid flows forward. There is no closed volume, as in a positive displacement pump, therefore producing a steady flow through the impeller. The pump basically increases the Bernoulli head of the flow between the eye and the exit of the pump.

Pumps Technology Summary

Advantages & Limitations

External Gear Pumps

Centrifugal Pumps

Maximum Flow Rate

42 L/min (11.1 gpm) (higher possible)

27 L/min (7.1 gpm)

Volume Displacement per Revolution

.017 ml

3 ml

Drive Speed rpm (maximum)

6000

10000

Maximum Differential Pressure

8.6 bar (125 psi) (higher possible)

~14 meters head (~46 ft head)

Accuracy and Repeatability

high

n/a

Autoclavability / Sterility

not with PTFE gears

not with PTFE components

Calibration / Recalibration

frequent

low frequency

Chemical Inertness

high

high

Corrosion Resistance

good

good

Cross-Contamination

yes (thorough flushing is required)

yes (thorough flushing is required)

Dead Volume

very low

low

Direct Contact with Mechanical Parts of the Pumphead

yes

yes

Run Dry

no

no

Fittings

hose barb or screw coupling

hose barb or screw coupling

Flow Rate Sensitivity to Differential Pressure

low

very high

Interchangeability of Pumpheads

easy

easy

Leakage Susceptibility

low

low

Maintenance (Time and Cost)

medium (service kits)

medium (service kits)

Multi-Channel Systems

no

no

Pulsation Ratio

very low

n/a

Pumping of High Viscosity Liquids

yes

no

Pumping of Suspensions, Sludges and Particles

yes

yes

Self-Priming

yes

no

Shearing Forces

moderate

low

Siphoning Effect When Pump Is Stopped

yes

yes

Suction Lift

dry: ~1.52 m (5 ft)

wet: ~3.96 m (13 ft)

n/a

Find a Distributor

Get a Quote

Find a Product

Headquarters

Micropump Inc.

1402 NE 136th Avenue

Vancouver, WA 98684-0818 USA